Lean Six Sigma Green Belt Certification at Lean Partner

Lean Six Sigma Green Belt certification is a great way to get a structured path to success, whether you want to advance your career or optimize organizational efficiency. Green Belts dedicate 10-25% of their time to improvement projects and make important contributions to their organizations through better problem-solving and data analysis skills.

You should know everything about becoming a Lean Six Sigma Green Belt to reshape the scene of your career path effectively.

Also read: Lean Six Sigma Belt Levels Explained

What is Six Sigma Green Belt Certification?

Lean Six Sigma Green Belt Certification represents a comprehensive mastery of process improvement methodologies that combine Lean principles and Six Sigma techniques. Green Belt certification gives professionals better problem-solving abilities focusing on the DMAIC (Define, Measure, Analyze, Improve, Control) model. People with Green Belts have a deep grasp of process improvement techniques and can use these skills to solve real-life organizational challenges.

It’s essential to understand that Green Belts is the backbone of organizational transformation, bridging the gap between strategic vision and tactical execution. Unlike Yellow Belts who support projects in limited capacities, Green Belts possess the analytical depth and project management skills to drive meaningful change across various business processes.

The Role of Green Belts in Organizations

Green Belt certified professionals are vital change agents in their organizations. Many call them the “workhorses” of process improvement efforts. We used them to lead smaller improvement projects while they support larger initiatives that Black Belts run. Their key tasks include:

- Collecting and analyzing data for process improvement

- Leading root cause analysis sessions

- Creating project charters with SIPOC (Supplier, Input, Process, Output, Customer) diagrams

- Building stronger teams through activities

- Fixing quality problems

Green Belts spend 10-50% of their work time on Six Sigma projects. They work in their areas while keeping up with their regular duties. They connect Six Sigma theory to practical use by turning complex ideas into real improvements.

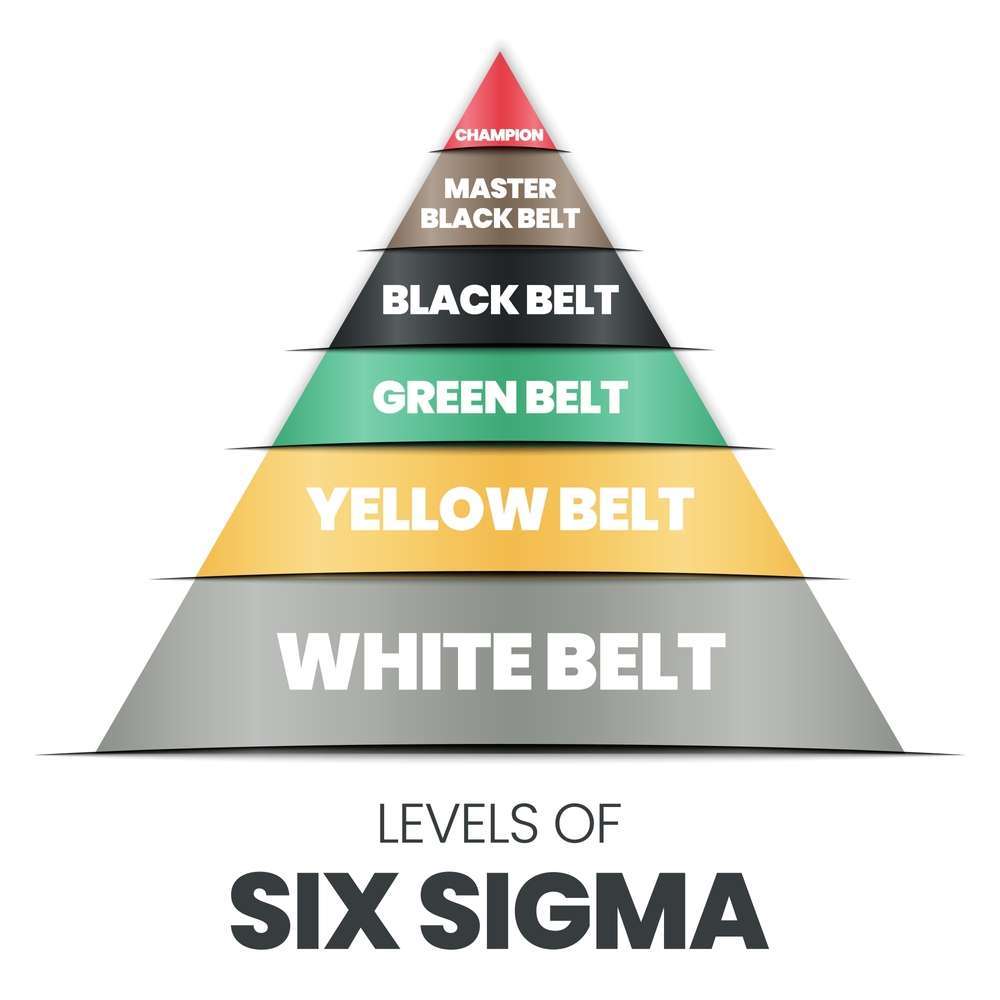

How Green Belt Fits into The Six Sigma Framework

Green Belts hold a strategic middle position in the Six Sigma hierarchy. They work hand in hand with Black Belts who spend all their time on improvement projects. The framework uses a structured belt system:

White/Yellow Belts: Focus on simple concepts and support roles Green Belts: Lead smaller projects and support Black Belt initiatives

Black Belts: Lead complex, cross-functional improvement projects

Master Black Belts (MBBs): Mentor Black Belts and provide advanced expertise

Green Belts strengthen this structure by analyzing quality problems and using the DMAIC methodology in their projects. They report to Black Belts on larger initiatives and help collect data and fix problems. They also lead their own teams of Yellow Belts or other staff members on smaller projects.

Key Differences Between Green Belt and other Belt Levels

The difference between Green Belts and other certification levels shows in project scope, expertise depth, and organizational role. Green Belts can lead improvement projects on their own, unlike Yellow Belts who stick to fundamentals. Compared to Black Belts, Green Belts usually:

- Work on smaller, department-specific projects instead of cross-functional initiatives

- Spend part of their time on Six Sigma work rather than full-time

- Use intermediate statistical tools instead of advanced ones

- Help with complex organizational changes rather than lead them

To get a Green Belt certification, you need to pass an exam with a minimum score of 70% or 280 out of 400 points. This varies based on the certifying body. ASQ, IASSC, and the Council for Six Sigma Certification are notable certifying organizations, each with slightly different requirements.

Most Green Belt certifications don’t expire, though requirements vary by provider. Training covers a complete study of DMAIC methodology, simple statistical tools, and project management techniques.

Six Sigma Green Belt certification is a great way to get analytical skills while maintaining your primary role. This makes it valuable especially when you have quality assurance, operations, logistics, and project management positions.

Join Lean Six Sigma Certification

Earn your Lean Six Sigma Green Belt certification at Lean Partner. Join our 5-day Virtual Class on August 11-22, 2025 via Microsoft Teams. Register with us today!

Take the first step—Enroll in our Lean Six Sigma course in Malaysia today!

Why Pursue Lean Six Sigma Green Belt Certification?

What sets apart high-performing organizations from their competitors? The answer often lies in their commitment to continuous improvement and process excellence. Green Belt certification equips professionals with the critical skills that can add value to your organization, such as:

Professional Skill Development

Six Sigma Green Belt certification gives you the versatile toolkit of skills you can use in a variety of industries like manufacturing, healthcare, IT, and finance. Certified Green Belts develop a detailed set of skills that has:

- Leadership abilities that enable them to guide teams through improvement projects

- Statistical competencies for evidence-based decision making

- Financial management expertise to calculate project benefits

- Process capability understanding to optimize operational outcomes

- Change management techniques to implement environmentally responsible improvements

Green Belts also become fluent in interpersonal communication, which becomes invaluable when presenting complex data to stakeholders. This certification builds a strong foundation to help problem solvers stay accountable while they improve processes and operations.

Increased Problem-Solving Abilities

Learning to solve complex problems is one of the biggest benefits you get with a Six Sigma Green Belt certification. Green Belt professionals quickly address complex issues by applying the DMAIC methodology—Define, Measure, Analyze, Improve, and Control.

Green Belts learn to:

- Identify the root causes of problems instead of just treating symptoms

- Stop issues before they get pricey internal disasters

- Apply analytical tools like Pareto charts, Fishbone diagrams, and FMEA (Failure Modes and Effects Analysis)

- Break down complex challenges into manageable components

These improvements will give a lasting and effective solution over time.

Enhanced Analytical Thinking

Green Belt certification promotes strong analytical thinking through evidence-based decision-making. Certified professionals learn about gathering, interpreting, and applying data to identify patterns and trends within processes.

This analytical mindset becomes especially useful when you have to predict process outcomes and establish control limits. Green Belts develop strong numerical skills to interpret data accurately and make informed decisions that improve processes and achieve project goals. These analytical capabilities help professionals to measure and calculate the financial benefits of any Six Sigma project they execute.

Greater Project Management Capabilities

Six Sigma Green Belt training substantially boosts project management abilities, though it’s primarily a technical certification. Certified Green Belts lead project teams, manage timelines, coordinate resources, and maintain focus on measurable outcomes.

Project documentation becomes natural to Green Belts as they document all process improvement work, including process charters, process maps, and customer requirements. Industry experts say Green Belts create standard processes that are easy to implement and help businesses achieve their goals.

The certification emphasizes creating a culture of continuous improvement. Professionals actively look for ways to boost processes and maintain efficiency over time. These certified individuals develop strategies that deliver long-term operational excellence and greater customer satisfaction.

Join Leadership Skills Training

Strong leaders drive success. Learn effective communication, decision-making, conflict resolution, and strategic leadership with our expert-led Leadership Skills Training Program. Whether you’re a team lead, manager, or executive, this program equips you to lead with confidence.

Boost your leadership potential—Join our Leadership Skills Training Program in Malaysia now!

Core Components of Our Lean Six Sigma Green Belt Certification

Getting a Six Sigma Green Belt starts with a good grasp of certification options. Our comprehensive Green Belt program delivers thorough training in both the theoretical foundations and practical applications of Lean Six Sigma. The curriculum focuses on developing four essential competency areas:

1. Process Analysis

Green Belts must excel at breaking down complex processes into manageable components.

At Lean Partner, our training covers:

- Process mapping techniques including SIPOC, swim lane diagrams, and value stream mapping

- Value-added analysis to identify and eliminate waste

- Process capability studies

- Root cause analysis methodologies including 5-Why and Fishbone diagrams

2. Data Driven Decision Making

The ability to collect, analyze, and interpret data forms the cornerstone of effective process improvement.

Participants learn:

- Measurement system analysis

- Descriptive statistics and probability distributions

- Hypothesis testing and confidence intervals

- Statistical process control using SigmaXL software

- Regression analysis and correlation studies

3. Complex Problem Solving

Green Belts tackle multifaceted problems using structured methodologies.

Our training emphasizes:

- DMAIC methodology (Define, Measure, Analyze, Improve, Control)

- Lean principles and waste reduction techniques

- Design of Experiments (DOE)

- Failure Mode and Effects Analysis (FMEA)

- Solution selection and prioritization tools

4. Project Management

Successful implementation requires strong project management capabilities.

Our program covers:

- Project charter development

- Stakeholder analysis and management

- Team dynamics and facilitation skills

- Change management techniques

- Project tracking and reporting methods

Certification Path and Requirements of Lean Six Sigma Green Belt Certification

Prerequisites

While prior experience with basic process improvement concepts is beneficial, our Green Belt program accommodates professionals from diverse backgrounds. It’s crucial to note that participants should possess:

- Basic knowledge of business processes

- Fundamental understanding of statistics

- Problem-solving aptitude

- Experience working in team environments

Training Structure and Mode

Online courses allow you to learn at your own pace, while in-person training follows fixed schedules that run for days or weeks. At Lean Partner, our Green Belt program follows a comprehensive approach:

- 5-day intensive training (40 hours total)

- Available in two formats:

- Live Virtual Training (May 19-23, 2025)

- Classroom Training (June 16-20, 2025)

- Hands-on workshops and simulation exercises

- Case studies and real-world applications

- Interactive coaching sessions

Examination and Project Requirements

Certification requires successful completion of:

- A written examination covering theoretical concepts and practical applications

- Practical project demonstrating the application of DMAIC methodology

- Project presentation showcasing results and lessons learned

Industry Recognition and Accreditation

Our Lean Six Sigma Green Belt Certification program maintains alignment with international standards and best practices. The certification is recognized by:

- International Association for Six Sigma Certification (IASSC)

- Council for Six Sigma Certification (CSSC)

This industry recognition ensures that your certification holds value across organizational boundaries and geographical regions.

Join Operational Excellence Training Program

Master process improvement, waste reduction, and efficiency strategies with expert-led training. Whether you’re a manager, team lead, or executive, this program equips you with the skills to drive continuous improvement and business success.

Achieve peak performance—Join our Operational Excellence Training Program now!

Advancing from Green Belt to Higher Levels

A well-laid-out career path exists for professionals who want to expand their expertise and make a bigger impact in their organizations after getting their Six Sigma Green Belt certification.

When to Pursue Black Belt Certification

The right time to move from Green Belt to Black Belt certification depends on your experience and success with projects. Most certification organizations suggest getting Black Belt after you have three years of full-time work experience in your field.

You might be ready to advance if you:

- Have finished one or two Green Belt projects successfully

- Feel comfortable using statistical analysis tools

- Have your organization’s backing for advanced training

The upgrade from Green Belt to Black Belt takes nine days of training. You’ll learn advanced statistical analysis and leadership skills. This training makes sense once you’ve become skilled at Green Belt concepts and can lead teams across departments.

Skills Gap Between Green and Black Belts

The difference between Green and Black Belts goes beyond just certification levels. Green Belts usually work on process improvement in their departments. Black Belts take on process design and state-of-the-art projects throughout the organization.

Black Belts have detailed knowledge of advanced statistical tools and ways to manage change. Green Belts might spend 10-25% of their time on improvement projects. Black Belts dedicate their full time to Six Sigma initiatives.

Leadership sets these roles apart too. Black Belts train and guide Green Belts while running several large-scale projects at once. They report directly to Six Sigma executives instead of department heads.

Creating a Six Sigma Career Path

Your strategic Six Sigma career growth needs these steps:

- Pick certification levels that match your career goals

- Look for hands-on opportunities that challenge you

- Get quality training from trusted providers

- Think about becoming a Master Black Belt after 5 years of Black Belt experience and finishing at least 10 Black Belt projects

Your Six Sigma experience should match your company’s needs and your career goals. Each new certification level brings more responsibility. Master Black Belts earn about MYR 116,675.26 more yearly than professionals without Six Sigma certifications.

Conclusion

Six Sigma Green Belt certification serves as a powerful career accelerator that helps professionals improve their process improvement expertise. This certification gives you the skills in statistical analysis and project management. Professionals with this certification become valuable team members in manufacturing, healthcare, and finance sectors.

Want to earn your Lean Six Sigma Green Belt certification at Lean Partner? Join our 5-day Virtual Class on August 18-22, 2025 via Microsoft Teams. Register with us today!

Dedication to the certification journey leads to substantial career rewards. Green Belt certified professionals command competitive salaries, particularly as they advance to Black Belt and Master Black Belt roles. Their expertise in optimizing processes through analytical insights makes them crucial team members in organizations.

Success in Six Sigma Green Belt certification stems from applying concepts in real situations. You should begin with small projects and gain confidence through hands-on experience before taking on complex initiatives. The certification creates a strong foundation to excel in quality-focused business environments, whether you lead department improvements or support company-wide transformations

FAQs About Green Belt Six Sigma Certification

How does Lean Six Sigma Green Belt certification differ from Yellow Belt and Black Belt?

Yellow Belt certification provides foundational knowledge of Lean Six Sigma concepts and basic problem-solving tools. Green Belt certification equips professionals to lead departmental improvement projects using statistical analysis and DMAIC methodology. Black Belt certification develops advanced expertise for leading complex, enterprise-level initiatives and mentoring Green Belts.

How challenging is the Six Sigma Green Belt certification exam?

While the Six Sigma Green Belt exam is demanding, it’s not insurmountable. With thorough preparation and understanding of Six Sigma methodologies, candidates can successfully pass the exam. Most certification bodies require a minimum score of 70% or 280 out of 400 points.

What are the career benefits of obtaining a Six Sigma Green Belt certification?

Six Sigma Green Belt certification enhances problem-solving abilities, analytical thinking, and project management skills. It opens up career opportunities across various industries, with certified professionals earning competitive salaries. In Malaysia, annual salaries for Green Belts can range from RM 15,000 to RM 221,000, depending on the role and experience.

How long does it typically take to complete Six Sigma Green Belt certification?

The timeframe for completing Six Sigma Green Belt certification varies based on the chosen program and individual circumstances. Self-paced online programs can take 2 to 7 weeks, while including project work can extend the process to 2-6 months. Factors affecting completion time include program format, project requirements, and available study time.

What’s the next step after obtaining a Six Sigma Green Belt certification?

After mastering Green Belt concepts and gaining experience, professionals can pursue Six Sigma Black Belt certification. This advancement typically requires at least three years of full-time work experience and successful completion of Green Belt projects. Black Belts focus on process design and innovation across the organization, often working full-time on Six Sigma initiatives and leading larger, more complex projects.