How Amazon Uses Six Sigma and You Can Too

If you’ve ever wondered how Amazon became a global powerhouse known for lightning-fast deliveries, seamless customer experiences, and relentless innovation, the answer lies in their relentless pursuit of operational excellence.

At the heart of Amazon’s success story is its dedication to Lean Six Sigma, a powerful combination of two proven methodologies designed to eliminate waste, reduce errors, and continuously improve processes. But here’s the good news: you don’t have to be a tech giant to benefit from these methods.

In this article, we’ll explore how Lean Six Sigma at Amazon works, real-world examples from inside the company, and practical steps you can take to apply the same principles in your own business.

History of Amazon

Jeff Bezos launched Amazon.com in 1994 as an online bookstore, and many doubted its chances of survival. However, the company quickly expanded beyond books, adding music, pet supplies, electronics, home improvement products, and pharmaceuticals to its offerings. Over the decade from 2000 to 2010, Amazon transformed from a digital bookstore into a vast marketplace supporting millions of third-party sellers, building a loyal customer base of over 30 million.

Today, Amazon stands as the undisputed leader among online retailers, and a key reason for this success is its rigorous and widespread application of Six Sigma principles across all departments. Below, we explore some unique ways Amazon’s Lean Six Sigma approach can inspire positive results for your business.

Amazon’s rapid expansion of product lines and introduction of innovative services—such as same-day delivery using automated drones—raises an important question: how did Amazon become the iconic leader in e-commerce? The answer lies in the integration of Lean Six Sigma principles throughout its operations.

While Amazon does not explicitly highlight Six Sigma in its public communications, the mindset and methodology have been deeply embedded in its processes for decades. Since 1999, when Jeff Wilke joined as Vice President of Operations, Lean Six Sigma has played a prominent role in shaping Amazon’s core business strategies.

As stated in Amazon’s 1999 Annual Report:

“Operational excellence: To us, operational excellence implies two things: delivering continuous improvement in customer experience and driving productivity, margin, efficiency, and asset velocity across all our businesses.”

Why Did Amazon Embrace Lean Six Sigma

From its early days as an online bookstore, Amazon faced the challenge of scaling rapidly while maintaining high standards. As the company grew, so did the complexity of its operations—warehouses, logistics, technology, and customer service all needed to run flawlessly.

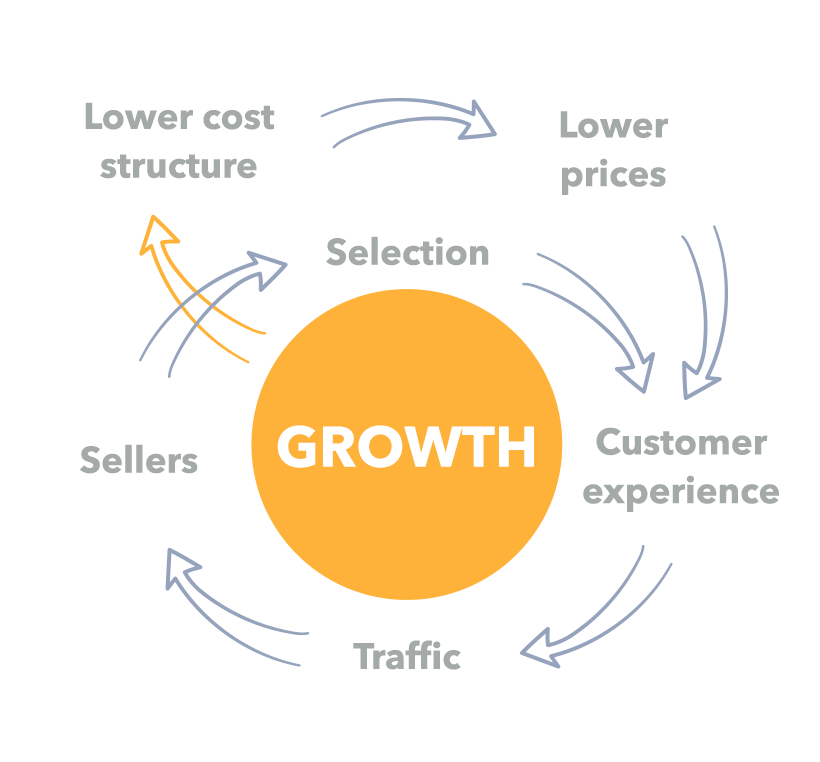

Amazon recognized that traditional management methods couldn’t keep up with this pace. By adopting Lean Six Sigma, Amazon could streamline operations, cut costs without sacrificing quality, deliver consistently excellent customer experiences, and foster a culture of innovation and problem-solving. This strategic move allowed Amazon to maintain agility and efficiency even as it expanded into new markets and services.

How Amazon Incorporated Six Sigma into Daily Work

While Six Sigma was originally developed to cut costs in manufacturing environments, its principles have proven to be highly adaptable across various industries—from healthcare and IT to retail and even the military.

Amazon, the world’s largest distributor and online retailer, is a prime example of how Six Sigma’s data-driven philosophy can be successfully applied beyond manufacturing. This is why the phrase “Amazon Lean Six Sigma” is often mentioned together.

Operational Excellence as a Cultural Pillar

At Amazon, Six Sigma is more than just a methodology. It’s a core element of the company culture. Operational excellence at Amazon means continuously improving the customer experience while boosting productivity, efficiency, and profit margins across all departments. With approximately 4,000 orders placed every minute, Amazon treats each order with utmost importance, ensuring that quality standards never slip.

Hiring the Right People to Drive Six Sigma

Amazon’s commitment to Six Sigma starts with hiring. The company strategically recruits top talent who are not only skilled but also aligned with its culture of continuous improvement. Moreover, Amazon invests heavily in training its workforce, encouraging employees to become certified Six Sigma Black Belts. Lean Six Sigma Black Belt Certification ensures that teams have the expertise needed to apply Six Sigma tools effectively and lead process improvements.

Applying Six Sigma Methods in Practice

Amazon leverages a variety of Six Sigma tools and techniques to reduce process variation and eliminate waste. Techniques such as Root Cause Analysis, DMAIC (Define, Measure, Analyze, Improve, Control), and the 5 Whys method are regularly used to identify inefficiencies and solve problems at their source. By removing non-value-added steps and fostering a Kaizen-inspired culture of ongoing improvement, Amazon continually refines its operations.

Also read: What’s the difference between Kaizen and Lean Six Sigma

Tangible Outcomes from Six Sigma Implementation

The impact of Six Sigma at Amazon is clear and measurable. The company has achieved significant gains in operational efficiency, enhanced inventory management, and stronger control over its value streams. These improvements not only reduce costs but also contribute directly to faster deliveries and better customer satisfaction—key drivers of Amazon’s competitive advantage.

Looking to optimize your business operations?

Connect with an experienced operation management consultant who can help tailor Lean Six Sigma strategies to boost efficiency and customer satisfaction in your organization!

How Lean Six Sigma Powers Amazon’s Success

1. Streamlined Warehousing and Fulfillment

Amazon’s fulfillment centers are the backbone of its promise to customers for fast and accurate delivery. Lean Six Sigma principles are deeply embedded in these operations to ensure that every package moves through the system with precision.

For example, Amazon employs standardized workflows that define each step an employee takes when picking, packing, and shipping products. This standardization reduces variability and ensures consistency across thousands of employees and dozens of fulfillment centers worldwide. Six Sigma techniques are used to identify common errors, such as mispicks or packaging mistakes, and then root causes are analyzed and eliminated. These improvements don’t just reduce mistakes; they also increase throughput, allowing Amazon to process more orders faster without compromising quality.

Moreover, Amazon fosters a culture of continuous improvement by encouraging employees to suggest process enhancements. This bottom-up approach ensures that frontline workers, who best understand the challenges, are empowered to contribute to operational excellence.

If you’re interested in deepening your understanding of these methodologies, exploring a Lean Six Sigma Yellow Belt Certification can provide structured knowledge and practical tools to implement similar improvements.

2. Data-Driven Decision Making

Amazon’s obsession with data is well-known, and Lean Six Sigma provides the perfect framework to harness this data effectively. Every process at Amazon is measured meticulously, from warehouse efficiency to customer satisfaction metrics.

When issues arise, such as delayed shipments or increased return rates, Amazon uses Six Sigma’s DMAIC methodology—Define, Measure, Analyze, Improve, Control—to systematically investigate the problem. This approach helps the company avoid knee-jerk reactions and instead focus on data-backed root causes. For instance, if a spike in late deliveries occurs, Amazon doesn’t just look at the surface symptoms; they analyze every step in the supply chain to pinpoint where delays originate, whether it’s a transportation bottleneck, inventory mismanagement, or a packaging issue.

This rigorous approach to problem-solving ensures that improvements are sustainable and measurable, making Amazon’s operations more resilient and responsive to change.

For professionals aiming to apply these data-driven techniques in their own teams, Lean Six Sigma Green Belt Certification offers practical guidance tailored to various industries and experience levels.

3. Customer-Centric Focus

At Amazon, the customer is at the heart of every process improvement initiative. Lean Six Sigma helps the company translate customer feedback into actionable changes that enhance satisfaction and loyalty.

Amazon actively collects Voice of the Customer (VOC) data through reviews, surveys, and customer service interactions. This rich feedback is analyzed to identify pain points and opportunities for improvement. For example, if customers report frequent issues with product packaging, Amazon uses Six Sigma tools to study the packaging process and redesign it to reduce damage during shipping.

By focusing on defect reduction—not just in products but in the entire customer experience—Amazon minimizes returns, refunds, and complaints. This relentless focus on quality and customer satisfaction drives repeat business and strengthens Amazon’s brand reputation.

If you’re looking to align your operations more closely with customer needs, consulting with an operation management consultant can help tailor Lean Six Sigma strategies to your unique challenges.

Also read: Why your business needs operation management consultant

4. Technology and Automation

Amazon’s pioneering use of robotics and artificial intelligence is a key factor in its operational success, but these technologies are implemented with Lean Six Sigma principles guiding their deployment.

Lean thinking helps Amazon identify the most impactful areas for automation, ensuring that investments deliver maximum efficiency gains. For example, robots are used to move inventory within warehouses, reducing the time employees spend walking and searching for products. This not only speeds up order fulfillment but also reduces physical strain on workers.

Additionally, Amazon applies the concept of error-proofing (known as Poka-Yoke in Lean Six Sigma) in its automated systems. These systems are designed to prevent mistakes before they happen—such as sensors that detect incorrect packaging or software that flags inventory discrepancies in real-time. This proactive approach reduces defects and keeps operations running smoothly.

Interested in mastering these proven strategies?

Discover how certification for Lean Six Sigma can equip you with the skills to drive operational excellence in your organization—just like Amazon!

Keep It Lean: How Amazon Streamlines Operations for Customer Satisfaction

Lean methodology complements Six Sigma by focusing on maximizing customer value while minimizing waste. Amazon has fully embraced this philosophy, embedding Lean innovation into its daily operations with one clear priority: enhancing customer satisfaction.

At its core, Lean is about delivering exactly what customers want—and only what they are willing to pay for. This means Amazon’s logistics and fulfillment systems must be incredibly efficient to ensure packages arrive on the promised date. Imagine a company that dedicates more workforce to fulfilling orders and providing excellent customer service than to engineering or back-end functions. This focus on value creation over unnecessary complexity is a hallmark of Lean thinking.

Empowering Employees to Stop Waste with Andon

Continuous improvement is another pillar of Lean, and Amazon has mastered this through tools like the Andon system. This Lean tool empowers employees to “stop the line” if they detect any issue that could harm customer value or experience. For example, if customer service agents notice repeated complaints about a product, they have the authority to halt its sale and recall inventory from warehouses—prioritizing customer satisfaction over short-term profits.

Amazon’s willingness to invest in opening more warehouses or adjusting operations—even at the cost of slimmer margins—demonstrates its commitment to delivering exceptional customer experiences. Every action is designed to eliminate wasteful activities that could negatively impact the customer.

Designing Smart Job Functions for Maximum Efficiency

Efficiency at Amazon also comes from thoughtfully designing each job function to reduce costs and optimize resource use. This smart approach protects the business from premature or uncontrolled growth by ensuring every role adds clear value to the process.

Building Business with Kaizen: Continuous Improvement in Action

For companies practicing Six Sigma, the ultimate goal is sustainable growth driven by continuous improvement. This is where Kaizen—the philosophy of making small, incremental changes—perfectly complements Lean and Six Sigma.

Amazon applies Kaizen through practices like the Gemba walk, which involves leaders visiting the “place where value is created” to observe operations firsthand. At Amazon, this often means the customer service or fulfillment departments.

During a Gemba walk, supervisors closely audit workflows, identify bottlenecks or inefficiencies and engage frontline employees to brainstorm creative solutions. Each Amazon distribution center has dedicated managers who regularly perform these walks, ensuring that continuous improvement is embedded in daily operations.

Even if your business isn’t as large as Amazon, adopting a similar approach—observing your processes closely and involving your team in problem-solving—can uncover valuable opportunities to improve efficiency and boost your bottom line.

Ready to unlock the power of Lean Six Sigma?

Take the first step toward transforming your operations by exploring our Lean Six Sigma training and gaining the tools to drive lasting success.

How You Can Apply Lean Six Sigma—No Matter Your Business Size

The beauty of Lean Six Sigma is that it’s not reserved for giant corporations. Whether you run a small business, startup, or growing enterprise, you can borrow Amazon’s playbook to improve your operations.

Start by identifying pain points in your processes—areas where delays, errors, or waste occur. Mapping your workflows will help you visualize these inefficiencies. Next, gather data on key metrics like task duration, error rates, and customer complaints. Even simple tracking can reveal valuable insights.

Involve your team by encouraging them to share ideas for improvement. Amazon’s success comes from empowering employees at all levels to participate in continuous improvement.

Use basic Lean Six Sigma tools such as the 5 Whys technique to uncover root causes, fishbone diagrams to visualize problems, and process mapping to identify waste. Focus on making incremental improvements—small changes can lead to big results over time.

Finally, celebrate your wins and foster a culture where continuous improvement is part of your company DNA. This mindset will help your business adapt and thrive.

Final Thoughts: Your Lean Six Sigma Journey Starts Now

Amazon’s story proves that Lean Six Sigma isn’t just corporate jargon—it’s a proven path to operational excellence, stellar customer experiences, and sustainable growth. By focusing on what matters most, involving your people, and committing to continuous improvement, you can build a business that’s not just efficient but exceptional.

Ready to take the first step? Map your processes, engage your team, and start improving today with Lean Partner. Your Lean Six Sigma success story awaits!