5 Whys: The Simple Question That Drives Big Results

5 Whys: The Simple Question That Drives Big Results

In today’s fast-paced business environment, leaders are constantly seeking ways to solve problems efficiently and improve organizational performance. One method that has gained widespread popularity in recent years is the “5 Whys” technique. Simple yet powerful, the 5 Whys approach encourages asking “Why?” multiple times to uncover the root cause of a problem. This article will delve into how the 5 Whys methodology works, its benefits, and its significant role in continuous improvement practices such as Lean, Six Sigma, and operational excellence. Additionally, we will explore real-world applications of the 5 Whys and how it has been employed by major corporations to achieve outstanding results.

Understanding the 5 Whys Methodology

The 5 Whys technique was originally created by Sakichi Toyoda, the founder of Toyota. The goal of the method is to identify the root cause of a problem by repeatedly asking “Why?” until the underlying issue is revealed. While the name suggests asking five times, the process might require fewer or more questions depending on the complexity of the problem. This simple yet effective approach allows teams to avoid surface-level fixes and instead address the core issues that are often overlooked in traditional problem-solving methods.

The 5 Whys methodology can be applied to various areas within a business, including product development, process improvement, customer service, and employee performance. Whether you’re dealing with a production delay, a quality control issue, or an internal communication breakdown, the 5 Whys method helps identify the true cause of a problem and enables teams to implement targeted solutions.

Why the 5 Whys Matter in Lean Six Sigma

Lean Six Sigma combines the efficiency-focused principles of Lean with the data-driven, defect-reduction approach of Six Sigma to create a powerful and comprehensive methodology for continuous improvement. By blending these two approaches, organizations are able to streamline processes, eliminate waste, and reduce variations, resulting in enhanced operational performance and greater effectiveness. It is often applied to improve product and service quality, reduce costs, and elevate customer satisfaction, helping businesses remain competitive in a fast-paced market.

The 5 Whys method is a core tool within Lean Six Sigma, helping companies dive deep into process problems and identify root causes that may not be immediately apparent. By repeatedly asking “why” to explore the cause-and-effect relationships underlying a problem, this method helps uncover the underlying issues and ensures that sustainable, long-term solutions are implemented. This process aids in eliminating waste (from Lean) and improving quality (from Six Sigma), guaranteeing that the true source of inefficiencies or defects is addressed to optimize processes and improve overall organizational performance.

For organizations striving to achieve efficiency, reliability, and consistency in their operations, applying the 5 Whys method as part of their Lean Six Sigma Training offers a strategic advantage. It empowers teams to make data-driven decisions and fosters a culture of continuous improvement, ultimately leading to more successful outcomes and a higher level of customer satisfaction.

How the 5 Whys Drive Business Process Improvement

The integration of the 5 Whys technique into business process improvement initiatives can yield significant and long-lasting results for organizations looking to enhance their efficiency and overall performance. One of the most well-known and widely applied methodologies for driving business process improvement is Lean Six Sigma, a combination of Lean principles (focused on reducing waste and optimizing resource usage) and Six Sigma techniques (focused on reducing variation and improving consistency). Both of these approaches share a common goal of fostering a culture of continuous improvement and focus on the importance of identifying and resolving root causes of issues or inefficiencies within business processes.

Using the 5 Whys as a tool within Lean Six Sigma projects enables organizations to dive deeper into their processes and systematically uncover inefficiencies that might not be immediately obvious or easily recognized. By continuously asking “Why?” at each step of the analysis, teams are able to isolate the true, underlying causes of inefficiencies and address them at their source, rather than just treating the symptoms. This method helps in uncovering both overt and subtle problems, ensuring that solutions are more targeted and effective. By continuously probing and addressing the root causes, organizations can achieve more sustainable improvements that have lasting impact. This approach not only leads to higher-quality products and services but also results in enhanced customer satisfaction, better alignment with customer needs, and greater profitability. Through such targeted improvements, businesses can reduce costs, improve operational efficiency, and gain a competitive edge in the market.

Real-World Case Studies: Lean Six Sigma – 5 Whys in Action

Many well-known companies have used the 5 Whys technique to drive meaningful results. Let’s take a closer look at some case studies of successful applications:

1. Toyota’s Lean Production System

In the 1930s, Sakichi Toyoda, the founder of Toyota, developed a straightforward method for uncovering the root cause of problems. His approach, known as the “Five Whys,” involved asking “Why?” repeatedly to trace the issue back to its origin. The process starts by identifying the problem and asking why it occurred. Then, based on the answer, another “Why?” is asked to dig deeper into the cause, continuing this cycle until the fundamental root cause is revealed. Typically, the fifth question would uncover the true underlying issue. This simple yet effective technique helped Toyota address problems at their core, rather than just fixing surface-level symptoms.

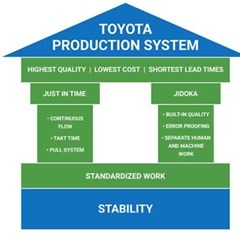

By the 1970s, the Five Whys methodology gained widespread popularity, especially in the manufacturing industry, where it was integrated into the Toyota Production System (TPS). This method was particularly valuable because it provided a clear and practical way to diagnose and solve problems, ensuring that companies could identify the real causes of inefficiencies or defects. It wasn’t long before the technique found applications in other sectors beyond manufacturing, including technology, where teams needed efficient ways to investigate incidents and resolve issues. The method’s simplicity and effectiveness made it an ideal tool for industries seeking to enhance problem-solving and improve operational processes.

Even today, Toyota continues to rely on the Five Whys to troubleshoot and solve problems within its production lines. The company uses this approach to quickly identify the root causes of mechanical failures, quality control issues, or operational bottlenecks. The Five Whys has remained a key part of Toyota’s culture of continuous improvement, ensuring that problems are addressed at their source to prevent recurrence. By applying this method, Toyota has been able to maintain high standards of quality, efficiency, and innovation, solidifying its position as a leader in the global automotive industry. Case Study Link

2. How Mod Mode Identified and Addressed a Decline in Website Traffic Using the Five Whys Methodology

Mod Mode, an online fashion retailer, faced a significant challenge when its website traffic dropped by 40% over the past three months. The decrease in traffic was concerning as it directly impacted potential sales and brand visibility. To identify the root cause of the problem, the CEO convened a meeting with the web developer, marketing manager, and customer support representative. Together, they used the Five Whys technique, a problem-solving tool designed to explore the cause-and-effect relationships underlying a specific issue.

By applying the Five Whys approach, the team quickly discovered that the core issue was that fewer people were being exposed to the site. This led them to realize that the decline in exposure was due to fewer people seeing the company’s digital ads. Digging deeper, they found that the ad campaign was no longer running on a major search engine, which had previously been a key platform for driving traffic. Upon further investigation, it became clear that the company’s account with the search engine was inactive because payments had not been processed.

The investigation revealed that the company’s credit card on file with the search engine had expired two months ago, and as a result, payments were missed, causing the ad campaign to be suspended. The team then discovered that when the company received new credit cards, the search engine account was not updated with the new information. This failure to update the payment method was traced back to the lack of a central system to track all services linked to the company’s credit card. Without a master list of services, the company overlooked updating its payment information, leading to the suspension of the ad campaign.

To prevent this issue from happening again, the team created an action plan. They decided to compile a master list of all services and subscriptions linked to the company’s credit card, including digital advertising accounts. In addition, they implemented regular reviews of all payment accounts and set up automated reminders to ensure timely updates when credit cards expire. By addressing the root cause and putting these measures in place, Mod Mode was able to restore its ad campaigns, increase website traffic, and streamline its account management processes to avoid similar problems in the future. Case Study Link

Conclusion

The 5 Whys technique is a powerful tool in uncovering the root causes of business problems and driving continuous improvement. Whether you are a manager, team leader, or consultant, applying the 5 Whys methodology can help you address challenges at their core, leading to better decision-making, improved efficiency, and a more agile business model. As demonstrated by major companies such as Toyota, adopting 5 Whys, Lean, Six Sigma, and operational excellence strategies can yield significant benefits for organizations of all sizes.

At Lean Partner, we are committed to helping organizations achieve operational excellence through proven methodologies like Lean, Six Sigma, and the 5 Whys technique. Whether you’re looking to pursue a Certification For Lean Six Sigma, or improve your business processes with the expertise of a Business Process Improvement Consultant, Lean Partner offers comprehensive services that drive lasting results.